Reprinted from Low Tech Magazine with Permission

Before the Industrial Revolution, people adjusted their energy demand to a variable energy supply. Our global trade and transport system — which relied on sail boats — operated only when the wind blew, as did the mills that supplied our food and powered many manufacturing processes.

The same approach could be very useful today, especially when improved by modern technology. In particular, factories and cargo transportation — such as ships and even trains — could be operated only when renewable energy is available. Adjusting energy demand to supply would make switching to renewable energy much more realistic than it is today.

Renewable Energy in Pre-Industrial Times

Before the Industrial Revolution, both industry and transportation were largely dependent on intermittent renewable energy sources. Water mills, windmills and sailing boats have been in use since Antiquity, but the Europeans brought these technologies to full development from the 1400s onwards.

At their peak, right before the Industrial Revolution took off, there were an estimated 200,000 wind powered mills and 500,000 water powered mills in Europe. Initially, water mills and windmills were mainly used for grinding grain, a laborious task that had been done by hand for many centuries, first with the aid of stones and later with a rotary hand mill.

However, soon water and wind powered mills were adapted to industrial processes like sawing wood, polishing glass, making paper, boring pipes, cutting marble, slitting metal, sharpening knives, crushing chalk, grinding mortar, making gunpowder, minting coins, and so on. [1-3] Wind- and water mills also processed a host of agricultural products. They were pressing olives, hulling barley and rice, grinding spices and tobacco, and crushing linseed, rapeseed and hempseed for cooking and lighting.

Even though it relied on intermittent wind sources, international trade was crucial to many European economies before the Industrial Revolution.

So-called ‘industrial water mills’ had been used in Antiquity and were widely adopted in Europe by the fifteenth century, but ‘industrial windmills’ appeared only in the 1600s in the Netherlands, a country that took wind power to the extreme. The Dutch even applied wind power to reclaim land from the sea, and the whole country was kept dry by intermittently operating wind mills until 1850. [1-3]

The use of wind power for transportation – in the form of the sailboat – also boomed from the 1500s onwards, when Europeans ‘discovered’ new lands. Wind powered transportation supported a robust, diverse and ever expanding international trading system in both bulk goods (such as grain, wine, wood, metals, ceramics, and preserved fish), luxury items (such as precious metals, furs, spices, ivory, silks, and medicin) and human slaves. [4]

Even though it relied on intermittent wind sources, international trade was crucial to many European economies. For example, the Dutch shipbuilding industry, which was centred around some 450 wind-powered saw mills, imported virtually all its naval stores from the Baltic: wood, tar, iron, hemp and flax. Even the food supply could depend on wind-powered transportation. Towards the end of the 1500s, the Dutch imported two thousand shiploads of grain per year from Gdansk. [4] Sailboats were also important for fishing.

Dealing with Intermittency in Pre-Industrial Times

Although variable renewable energy sources were critical to European society for some 500 years before fossil fuels took over, there were no chemical batteries, no electric transmission lines, and no balancing capacity of fossil fuel power plants to deal with the variable energy output of wind and water power. So, how did our ancestors deal with the large variability of renewable power sources?

To some extent, they were counting on technological solutions to match energy supply to energy demand, just as we do today. The water level in a river depends on the weather and the seasons. Boat mills and bridge mills were among the earliest technological fixes to this problem. They went up and down with the water level, which allowed them to maintain a more predictable operating regime. [1-2]

To some extent, our ancestors were counting on technological solutions to match energy supply to energy demand, just as we do today.

However, water power could also be stored for later use. Starting in the middle ages, dams were built to create mill ponds, a form of energy storage that’s similar to today’s hydropower reservoirs. The storage reservoirs evened out the flow of streams and insured that water was available when it was needed. [2] [5]

But rivers could still dry out or freeze over for prolonged periods, rendering dams and adjustable water wheels useless. Furthermore, when one counted on windmills, no such technological fixes were available. [3] [6-7]

A technological solution to the intermittency of both water and wind power was the ‘beast mill’ or ‘horse mill’. [8] In contrast to wind and water power, horses, donkeys or oxen could be counted on to supply power whenever it was required. However, beast mills were expensive and energy inefficient to operate: feeding a horse required a land area capable of feeding eight humans. [9] Consequently, the use of animal power in large-scale manufacturing processes was rare. Beast mills were mostly used for the milling of grain or as a power source in small workshop settings, using draft animals. [1]

Obviously, beast mills were not a viable backup power source for sailing ships either. In principle, sailing boats could revert to human power when wind was not available. However, a sufficiently large rowing crew needed extra water and food, which would have limited the range of the ship, or its cargo capacity. Therefore, rowing was mainly restricted to battleships and smaller boats.

Adjusting Demand to Supply: Factories

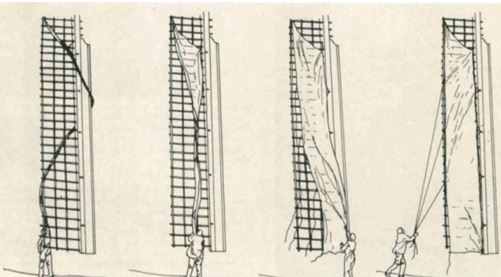

Because of their limited technological options for dealing with the variability of renewable energy sources, our ancestors mainly resorted to a strategy that we have largely forgotten about: they adapted their energy demand to the variable energy supply. In other words, they accepted that renewable energy was not always available and acted accordingly. For example, windmills and sailboats were simply not operated when there was no wind.

In industrial windmills, work was done whenever the wind blew, even if that meant that the miller had to work night and day, taking only short naps. For example, a document reveals that at the Union Mill in Cranbrook, England, the miller once had only three hours sleep during a windy period lasting 60 hours. [3] A 1957 book about windmills, partly based on interviews with the last surviving millers, reveals the urgency of using wind when it was available:

Often enough when the wind blew in autumn, the miller would work from Sunday midnight to Tuesday evening, Wednesday morning to Thursday night, and Friday morning to Saturday midnight, taking only a few snatches of sleep; and a good windmiller always woke up in bed when the wind rose, getting up in the middle of the night to set the mill going, because the wind was his taskmaster and must be taken advantage of whenever it blew. Many a village has at times gone short of wheaten bread because the local mill was becalmed in a waterless district before the invention of the steam engine; and barley-meal bread or even potato bread had to suffice in the crisis of a windless autumn. [10]

In earlier, more conservative times, the miller was punished for working on Sunday, but he didn’t always care. When a protest against Sunday work was made to Mr. Wade of Wicklewood towermill, Norfolk, he retorted: “If the Lord is good enough to send me wind on a Sunday, I’m going to use it”. [11] On the other hand, when there was no wind, millers did other work, like maintaining their machinery, or took time off. Noah Edwards, the last miller of Arkley tower mill, Hertfordshire, would “sit on the fan stage of a fine evening and play his fiddle”. [11]

Adjusting Demand to Supply: Sailboats

A similar approach existed for overseas travel, using sail boats. When there was no wind, sailors stayed ashore, maintained and repaired their ships, or did other things. They planned their trips according to the seasons, making use of favourable seasonal winds and currents. Winds at sea are not only much stronger than those over land, but also more predictable.

Sailors planned their trips according to the seasons, making use of favourable seasonal winds and currents.

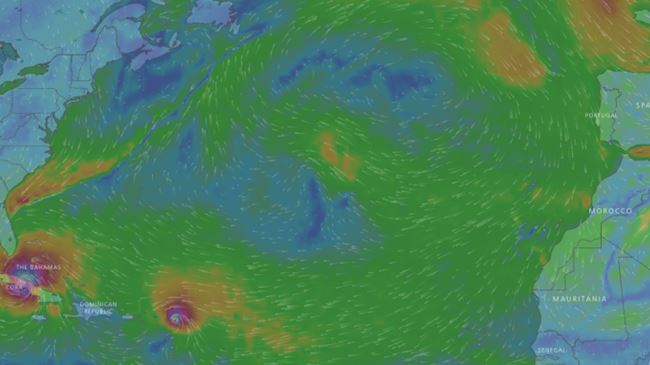

The lower atmosphere of the planet is encircled by six major wind belts, three in each hemisphere. From Equator to poles these ‘prevailing winds’ are the trade winds, the westerlies, and the easterlies. The six wind belts move north in the northern summer and south in the northern winter. Five major sea current gyres are correlated with the dominant wind flows.

Gradually, European sailors deciphered the global pattern of winds and currents and took full advantage of them to establish new sea routes all over the world. By the 1500s, Christopher Columbus had figured out that the combination of trade winds and westerlies enabled a round-trip route for sailing ships crossing the Atlantic Ocean.

The trade winds reach their northernmost latitude at or after the end of the northern summer, bringing them in reach of Spain and Portugal. These summer trade winds made it easy to sail from Southern Europe to the Caribbean and South America, because the wind was blowing in that direction along the route.

Taking the same route back would be nearly impossible. However, Iberian sailors first sailed north to catch the westerlies, which reach their southernmost location at or after the end of winter and carried the sailors straight back to Southern Europe. In the 1560s, Basque explorer Andrés de Urdaneta discovered a similar round-trip route in the Pacific Ocean. [12]

The use of favourable winds made travel times of sailboats relatively reliable. The fastest Atlantic crossing was 21 days, the slowest 29 days.

The use of favourable winds made the travel times of sailboats relatively predictable. Ocean Passages for the Worldmentions that typical passage times from New York to the English Channel for a mid-19th to early 20th century sailing vessel was 25 to 30 days. From 1818 to 1832, the fastest crossing was 21 days, the slowest 29 days. [13]

The journey from the English Channel to New York took 35-40 days in winter and 40-50 days in summer. To Cape Town, Melbourne, and Calcutta took 50-60 days, 80-90 days, and 100-120 days, respectively. [13] These travel times are double to triple those of today’s container ships, which vary their speed based on oil prices and economic demand.

Old Approach, New Technology

As a strategy to deal with variable energy sources, adjusting energy demand to renewable energy supply is just as valuable a solution today as it was in pre-industrial times. However, this does not mean that we need to go back to pre-industrial means. We have better technology available, which makes it much easier to synchronise the economic demands with the vagaries of the weather.

In the following paragraphs, I investigate in more detail how industry and transportation could be operated on variable energy sources alone, and demonstrate how new technologies open new possibilities. I then conclude by analysing the effects on consumers, workers, and economic growth.

Industrial Manufacturing

On a global scale, industrial manufacturing accounts for nearly half of all energy end use. Many mechanical processes that were run by windmills are still important today, such as sawing, cutting, boring, drilling, crushing, hammering, sharpening, polishing, milling, turning, and so on. All these production processes can be run with an intermittent power supply.

The same goes for food production processes (mincing, grinding or hulling grains, pressing olives and seeds), mining and excavation (picking and shovelling, rock and ore crushing), or textile production (fulling cloth, preparing fibres, knitting and weaving). In all these examples, intermittent energy input does not affect the quality of the production process, only the production speed.

Many production processes are not strongly disadvantaged by an intermittent power supply.

Running these processes on variable power sources has become a lot easier than it was in earlier times. For one thing, wind power plants are now completely automated, while the traditional windmill required constant attention. [14]

However, not only are wind turbines (and water turbines) more practical and powerful than in earlier times, we can now make use of solar energy to produce mechanical energy. This is usually done with solar photovoltaic (PV) panels, which convert sunlight into electricity to run an electric motor.

Consequently, a factory that requires mechanical energy can be run on a combination of wind and solar power, which increases the chances that there’s sufficient energy to run its machinery. The ability to harvest solar energy is important because it’s by far the most widely available renewable power source. Most of the potential capacity for water power is already taken. [15]

Thermal Energy

Another crucial difference with pre-industrial times is that we can apply the same strategy to basic industrial processes that require thermal energy instead of mechanical energy. Heat dominates industrial energy use, for instance, in the making of chemicals or microchips, or in the smelting of metals.

In pre-industrial times, manufacturing processes that required thermal energy were powered by the burning of biomass, peat and/or coal. The use of these energy sources caused grave problems, such as large-scale deforestation, loss of land, and air pollution. Although solar energy was used in earlier times, for instance, to evaporate salt along seashores, to dry crops for preservation, or to sunbake clay bricks, its use was limited to processes that required relatively low temperatures.

We can apply the same strategy to basic industrial processes that require thermal energy instead of mechanical energy, which was not possible before the Industrial Revolution.

Today, renewable energy other than biomass can be used to produce thermal energy in two ways. First, we can use wind turbines, water turbines or solar PV panels to produce electricity, which can then be used to produce heat by electrical resistance. This was not possible in pre-industrial times, because there was no electricity.

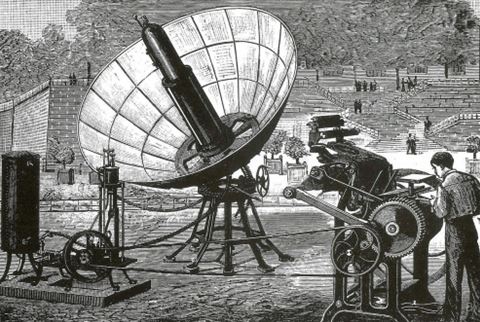

Second, we can apply solar heat directly, using water-based flat plate collectors or evacuated tube collectors, which collect solar radiation from all directions and can reach temperatures of 120 degrees celsius. We also have solar concentrator collectors, which track the sun, concentrate its radiation, and can generate temperatures high enough to melt metals or produce microchips and solar cells. These solar technologies only became available in the late 19th century, following advances in the manufacturing of glass and mirrors.

Limited Energy Storage

Running factories on variable power sources doesn’t exclude the use of energy storage or a backup of dispatchable power plants. Adjusting demand to supply should take priority, but other strategies can play a supportive role. First, energy storage or backup power generation capacity could be useful for critical production processes that can’t be halted for prolonged periods, such as food production.

Second, short-term energy storage is also useful to run production processes that are disadvantaged by an intermittent power supply. [16] Third, short-term energy storage is crucial for computer-controlled manufacturing processes, allowing these to continue operating during short interruptions in the power supply, and to shut down safely in case of longer power cuts. [17]

Compared to pre-industrial times, we now have more and better energy storage options available. For example, we can use biomass as a backup power source for mechanical energy production, something pre-industrial millers could not do – before the arrival of the steam engine, there was no way of converting biomass into mechanical energy.

Before the arrival of the steam engine, there was no way of converting biomass into mechanical energy.

We also have chemical batteries, and we have low-tech systems like flywheels, compressed air storage, hydraulic accumulators, and pumped storage plants. Heat energy can be stored in well-insulated water reservoirs (up to 100 degrees) or in salt, oil or ceramics (for much higher temperatures). All these storage solutions would fail for some reason or another if they were tasked with storing a large share of renewable energy production. However, they can be very useful on a smaller scale in support of demand adjustment.

The New Age of Sail

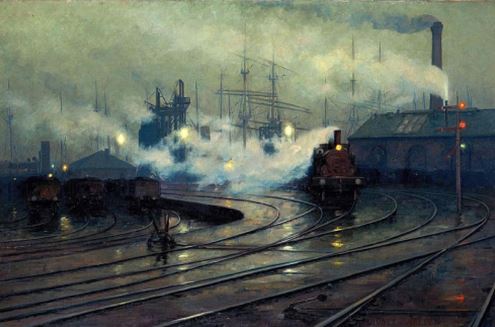

Cargo transportation is another candidate for using renewable power when it’s available. This is most obvious for shipping. Ships still carry about 90 percent of the world’s trade, and although shipping is the most energy efficient way of transportation per tonne-kilometre, total energy use is high and today’s oil powered vessels are extremely polluting.

A common high-tech idea is to install wind turbines off-shore, convert the electricity they generate into hydrogen, and then use that hydrogen to power seagoing vessels. However, it’s much more practical and energy efficient to use wind to power ships directly, like we have done for thousands of years. Furthermore, oil powered cargo ships often float idle for days or even weeks before they can enter a port or leave it, which makes the relative unpredictability of sailboats less problematic.

It’s much more practical and energy efficient to use wind to power ships directly.

As with industrial manufacturing, we now have much better technology and knowledge available to base a worldwide shipping industry on wind power alone. We have new materials to build better and longer-lasting ships and sails, we have more accurate navigation and communication instruments, we have more predictable weather forecasts, we can make use of solar panels for backup engine power, and we have more detailed knowledge about winds and currents.

In fact, the global wind and current patterns were only fully understood when the age of sail was almost over. Between 1842 and 1861, American navigator Matthew Fontaine Maury collected an extensive array of ship logs which enabled him to chart prevailing winds and sea currents, as well as their seasonal variations. [18]

Maury’s work enabled seafarers to shorten sailing time considerably, by simply taking better advantage of prevailing winds and sea currents. For instance, a journey from New York to Rio de Janeiro was reduced from 55 to 23 days, while the duration of a trip from Melbourne to Liverpool was halved, from 126 to 63 days. [18]

More recently, yacht racing has generated many innovations that have never been applied to commercial shipping. For example, in the 2017 America’s Cup, the Emirates Team New Zealand introduced stationary bikes instead of hand cranks to power the hydraulic system that steers the boat. Because our legs are stronger than our arms, pedal powered ‘grinding’ allows for quicker tacking and gybing in a race, but it could also be useful to reduce the required manpower for commercial sailing ships. [19]

Speed sailing records are also telling. The fastest sailboat in 1972 did not even reach 50 km/h, while the current record holder — the Vestas Sailrocket 2 — sailed at 121 km/h in 2012. While these types of ships are not practical to carry cargo, they could inspire other designs that are.

Wind & Solar Powered Trains

We could follow a similar approach for land-based transportation, in the form of wind and solar powered trains. Like sailing boats, trains could be running whenever there is renewable energy available. Not by putting sails on trains, of course, but by running them on electricity made by solar PV panels or wind turbines along the tracks. This would be an entirely new application of a centuries-old strategy to deal with variable energy sources, only made possible by the invention of electricity.

Wind and solar powered trains would be an entirely new application of a centuries-old strategy to deal with variable energy sources.

Running cargo trains on renewable energy is a great use of intermittent wind power because they are usually operated at night, when wind power is often at its best and energy demand is at its lowest. Furthermore, just like cargo ships, cargo trains already have unreliable schedules because they often sit stationary in train-yards for days, waiting to become fully loaded.

Even the speed of the trains could be regulated by the amount of renewable energy that is available, just as the wind speed determines the speed of a sailing ship. A similar approach could also work with other electrical transportation systems, such as trolleytrucks, trolleyboats or aerial ropeways.

Combining solar and wind powered cargo trains with solar and wind powered factories creates extra possibilities. For example, at first sight, solar or wind powered passenger trains appear to be impossible, because people are less flexible than goods. If a solar powered train is not running or is running too slow, an appointment may have to be rescheduled at the last minute. Likewise, on cloudy days, few people would make it to the office.

However, this could be solved by using the same renewable power sources for factories and passenger trains. Solar panels along the railway lines could be sized for cloudy days, and thus guarantee a minimum level of energy for a minimum service of passenger trains (but no industrial production). During sunny days, the extra solar power could be used to run the factories along the railway line, or to run extra passenger (or cargo) trains.

Consequences for Society: Consumption & Production

As we’ve seen, if industrial production and cargo transportation became dependent on the availability of renewable energy, we would still be able to produce a diverse range of consumer goods, and transport them all over the globe. However, not all products would be available all the time. If I want to buy new shoes, I might have to wait for the right season to get them manufactured and delivered.

Production and consumption would depend on the weather and the seasons. Solar powered factories would have higher production rates in the summer months, while wind powered factories would have higher production rates in the winter months. Sailing seasons also need to be taken into account.

If I want to buy new shoes, I might have to wait for the right season to get them manufactured and delivered.

But running an economy on the rhythms of the weather doesn’t necessarily mean that production and consumption rates would go down. If factories and cargo transportation adjust their energy use to the weather, they can use the full annual power production of wind turbines and solar panels.

Manufacturers could counter seasonal production shortages by producing items ‘in season’ and then stocking it close to consumers for sale during low energy periods. In fact, the products themselves would become ‘energy storage’ in this scenario. Instead of storing energy to manufacture products in the future, we would manufacture products whenever there is energy available, and store the products for later sale instead.

However, seasonal production may well lead to lower production and consumption rates. Overproducing in high energy times requires large production facilities and warehouses, which would be underused for the rest of the year. To produce cost-efficiently, manufacturers will need to make compromises. From time to time, these compromises will lead to product shortages, which in turn could encourage people to consider other solutions, such as repair and re-use of existing products, crafted products, DIY, or exchanging and sharing goods.

Consequences for the Workforce

Adjusting energy demand to energy supply also implies that the workforce adapts to the weather. If a factory runs on solar power, then the availability of power corresponds very well with human rhythms. The only downside is that workers would be free from work especially in winter and on cloudy days.

However, if a factory or a cargo train runs on wind power, then people will also have to work during the night, which is considered unhealthy. The upside is that they would have holidays in summer and on good weather days.

If a factory or a transportation system is operated by wind or solar energy alone, workers would also have to deal with uncertainty about their work schedules. Although we have much better weather forecasts than in pre-industrial times, it remains difficult to make accurate predictions more than a few days ahead.

However, it is not only renewable power plants that are now completely automated. The same goes for factories. The last century has seen increasing automation of production processes, based on computers and robots. So-called “dark factories” are already completely automated (they need no lights because there is nobody there).

It’s not only renewable power plants that are now completely automated. The same goes for factories.

If a factory has no workers, it doesn’t matter when it’s running. Furthermore, many factories already run for 24 hours per day, partly operated by millions of night shift workers. In these cases, night work would actually decrease because these factories will only run through the night if it’s windy.

Finally, we could also limit the main share of industrial manufacturing and railway transportation to normal working hours, and curtail the oversupply during the night. In this scenario, we would simply have less material goods and more holidays. On the other hand, there would be an increased need for other types of jobs, like craftsmanship and sailing.

What About the Internet?

In conclusion, industrial manufacturing and cargo transportation — both over land and over sea — could be run almost entirely on variable renewable power sources, with little need for energy storage, transmission networks, balancing capacity or overbuilding renewable power plants. In contrast, the modern high-tech approach of matching energy supply to energy demand at all times requires a lot of extra infrastructure which makes renewable power production a complex, slow, expensive and unsustainable undertaking.

Adjusting energy demand to supply would make switching to renewable energy much more realistic than it is today. There would be no curtailment of energy, and no storage and transmission losses. All the energy produced by solar panels and wind turbines would be used on the spot and nothing would go to waste.

Admittedly, adjusting energy demand to energy supply can be less straightforward in other sectors. Although the internet could be entirely operated on variable power sources — using asynchronous networks and delay-tolerant software — many newer internet applications would then disappear.

At home, we probably can’t expect people to sit in the dark or not to cook meals when there is no renewable energy. Likewise, people will not come to hospitals only on sunny days. In such instances, there is a larger need for energy storage or other measures to counter an intermittent power supply. That’s for a next post.

Kris De Decker. Edited by Jenna Collett.

Part of the research for this article happened during a fellowship at the Demand Centre, Lancaster, UK.

Sources:

[1] Lucas, Adam. Wind, Water, Work: Ancient and Medieval Milling Technology. Vol. 8. Brill, 2006.

[2] Reynolds, Terry S. Stronger than a hundred men: a history of the vertical water wheel. Vol. 7. JHU Press, 2002.

[3] Hills, Richard Leslie. Power from wind: a history of windmill technology. Cambridge University Press, 1996.

[4] Paine, Lincoln. The sea and civilization: a maritime history of the world. Atlantic Books Ltd, 2014.

[5] One of the earliest large hydropower dams was the Cento dam in Italy (1450), which was 71 m long and almost 6 m high. By the 18th century, the largest dams were up to 260 m long and 25 m high, with power canals leading to dozens of water wheels. [2]

[6] Although windmills had all kinds of internal mechanisms to adapt to sudden changes in wind speed and wind direction, wind power had no counterpart for the dam in water power.

[7] This explains why windmills became especially important in regions with dry climates, in flat countries, or in very cold areas, where water power was not available. In countries with good water resources, windmills only appeared when the increased demand for power created a crisis because the best waterpower sites were already occupied.

[8] Tide mills were technically similar to water mills, but they were more reliable because the sea is less prone to dry out, freeze over, or change its water level than a river.

[9] Sieferle, Rolf Peter, and Michael P. Osman. The subterranean forest: energy systems and the industrial revolution. Cambridge: White Horse Press, 2001.

[10] Freese, Stanley. Windmills and millwrighting. Cambridge University Press, 1957

[11] Wailes, Rex. The English windmill. London, Routledge & K. Paul, 1954

[12] The global wind pattern is complemented by regional wind patterns, such as land and sea breezes. The Northern Indian Ocean has semi-annually reversing Monsoon winds. These blow from the southwest from June to November, and from the northeast from December to May. Maritime trade in the Indian Ocean started earlier than in other seas, and the established trade routes were entirely dependent on the season.

[13] Jenkins, H. L. C. “Ocean passages for the world.” The Royal Navy, Somerset (1973).

[14] Windmillers had to be alert to keep the gap between the stones constant however choppy the wind, and before the days of the centrifugal governor this was done by hand. The miller had to watch the power of the wind, to judge how much sail cloth to spread, and to be prepared to stop the mill under sail and either take in or let out more cloth, for there were no patent sails. And before the fantail came into use, he had to watch the direction of the wind as well and keep the sails square into the wind’s eye. [11]

[15] Apart from electricity, the Industrial Revolution also brought us compressed air, water under pressure, and improved mechanical power transmission, which can all be valuable alternatives for electricity in certain applications.

[16] A similar distinction was made in the old days. For example, when spinning cloth, a constant speed was required to avoid gearwheels hunting and causing the machines to deliver thick and thin parts in rovings or yarns. [3] That’s why spinning was only mechanised using water power, which could be stored to guarantee a more regular power supply, and not wind power. Wind power was also unsuited for processes like papermaking, mine haulage, or operating blast furnace bellows in ironworks.

[17] Very short-term energy storage is required for many mechanical production processes running on variable power sources, in order to smooth out small and sudden variations in energy supply. Such mechanical systems were already used in pre-industrial windmills.

[18] Leighly, J. (ed) (1963) The Physical Geography of the Sea and its Meteorology by Matthew Fontaine Maury, 8th Edition, Cambridge, MA: Belknap Press. Cited by Knowles, R.D. (2006) “Transport shaping space: the differential collapse of time/space”, Journal of Transport Geography, 14(6), pp. 407-425.

[19] Rival teams rejected pedal power because they feared radical change, says Team New Zealand designer. The Telegraph, May 24, 2017.

Leave a Reply